Properties of FFKM O-rings

FFKM O-rings combine the sealing force, resistance and recovery of a regular elastomer O-ring with the added chemical resistance of PTFE.

FFKM O-ring specifications

Our high quality FFKM materials are designed to deliver the highest levels of performance and extend the service life of your FFKM O-rings.

FFKM O-ring applications

FFKM O-rings are used wherever chemical resistance is paramount, including the oil and gas, aerospace and chemical processing industries.

Buying FFKM O-rings & seals

Our innovative FFKM O-rings and seals are produced under the strictest process control conditions to deliver consistently reliable performance.

FFKM Hub

Perfluoroelastomers (FFKM) are a remarkable family of chemical and heat-resistant elastomers. Following the development of fluoroelastomers (FKM) in the 1950s, demand grew for a more chemically resistant polymer with the ability to withstand higher temperatures. Perfluoroelastomers were born out of this necessity in the late 1960s, combining the chemical resistance of PTFE with the flexibility and elasticity of regular FKMs.

Opportunities to buy FFKM were initially scarce and were limited to chemical processes and space programmes. But the versatility and durability of FFKM quickly saw it rolled out across a much wider range of applications. To the extent that perfluoroelastomers are now widely used as high-performance FFKM O-rings, that are extensively used in chemical processing and transport, oil and gas, semiconductor, and aerospace industries, reducing downtime and extending service life across many industrial processes.

TRP Polymer Solutions have developed a range of perfluoroelastomer materials suitable for a huge variety of industries and applications. FFKM O-rings, seals and gaskets are the most common products that we manufacture. In pursuit of excellence, we developed our own unique TRPlast™ range of FFKM, which offers the highest levels of performance and can often be used in applications where other polymers simply wouldn’t cope.

TRPlast® 260B

This FFKM is a cost-effective sealing solution for aggressive chemical and high-temperature environments.

This material provides the best-in-class chemical resistance – including resistance to Acids, Alcohols, Amines, Esters, Ketones, Steam & Hot Water, and Strong oxidisers covers approximately 90% of all FFKM applications.

Its low permeation resistance to a broad range of chemicals, and excellent physical properties, with outstanding compression set resistance make it great for a variety of applications that require optimum mean time between replacement

TRPlast® 260B is commonly used in:

- Chemical processing industry

- Mixed chemical streams

- High strength acids/bases/alkali

- Motorsport

- High ethanol fuels / Synthetic fuel blends

- Aerospace and defence

- Chemical transportation industry

- Oil and gas

TRPlast® 300B

TRPlast® 300B Offers a longer service life than TRPlast® 260B at elevated temperatures with a market leading compression set resistance. This material has excellent compression set resistance even when tested to 6000+ Hours at 200oC. Its high chemical resistance, with performance to 300oC in steam, makes it a great choice over competitors.

TRPlast® 300B is commonly used in:

- Chemical processing & applications requiring hot water resistance up to 300oC

- Chemical processing & applications requiring steam resistance up to 300oC

- Mixed chemical streams

- High strength acids/bases/alkalis

- Motorsport

- High ethanol fuels / Synthetic fuel blends

- Aerospace and defence

- Chemical transportation industry

- Oil and gas

Thermal testing data against competitors

The data above shows that when TRPlast 300B is compared to competitor materials which also specify equivalent or higher max temperatures, TRPlast 300B maintains its sealing force for longer.

(Long term compression set results at 200oC on BS214 O-Rings)

TRPlast 300B has been continuously tested beyond 6000 Hours.

(Long term compression set results at 200C on BS214 O-Rings)

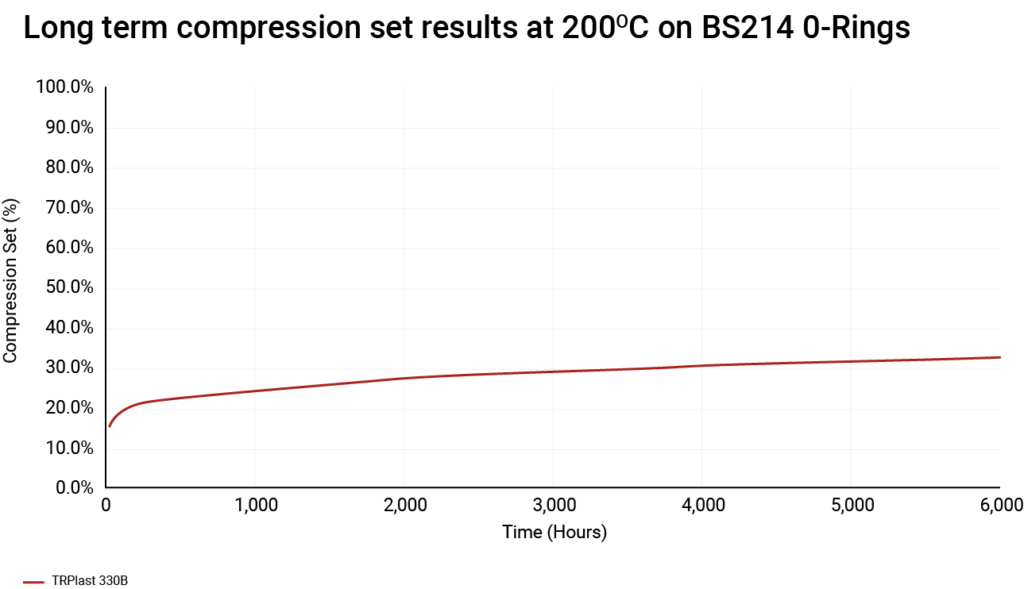

TRPlast® 330B

TRPlast® 330B has an exceptional chemical resistance, with best in class thermal resistance up to 330oC. When tested against materials claiming 350oC max temperature, service life was over 300% longer. Although there are no regulations to determine the max temperature of use that a manufacturer can place on a datasheet, TRP always recommends comparing test data between manufacturers where possible.

Thermal testing data against competitors:

The data above shows that when TRPlast 330B was compared to materials claiming equal or greater max temperature on their datasheet, the material had a service life of approximately 400% longer.

TRPlast®330B currently has over 6000 Hours of testing

Note: TRPlast® 330B is not suitable for steam, hot water or amines at elevated temperatures.

TRPlast® LT45

TRPlast® LT45 has a high chemical resistance, with a best in class low-temperature capability of -45oC in static conditions, with a TR10 of -30°c . This proprietary technology provides outstanding low temperature performance in static and dynamic applications, where other materials may be unable to seal. This material has a high-temperature performance up to 240oC.

TRPlast® LT45 is commonly used in:

- Chemical processing & applications requiring hot water and steam resistance

- Mixed chemical streams

- High strength acids/bases/alkalis

- High ethanol fuels / Synthetic fuel blends

- Aerospace and defence

- Chemical transportation industry

- Oil and gas

TRPlast® LT45 is also proven for use in space applications.

What are TRP’s Production Capabilities

We manufacture FFKM mouldings and O-Rings on short lead times of 10-14 days. We are a UK-based manufacturer, and worldwide supplier who is happy to supply quantities from 1 pcs to 100,000+, with no minimum order quantities for FFKM.

We produce tooling in-house with rapid lead times for non-standard-sized FFKM O-Rings.

Our materials technologists are happy to advise on material compatibility and customer-specific applications. We can offer in-house testing including chemical compatibility, physical properties, and load deflections for seal design analysis. We also have links to UK and European test houses for further specific testing.

In addition to FFKM O-rings, we can also supply punched, waterjet cut or laser-cut FFKM gaskets for the rapid delivery of prototypes without the need for tooling.

TRP Polymer Solutions are also accredited to ISO 9001/ 14001 / 45001, discover more about our quality, health and safety and environmental processes.

Buy FFKM seals at TRP Polymer Solutions

Quality is built into every aspect of the TRPlast® philosophy. As such, our FFKM O-rings and seals are produced under the strictest process control conditions to deliver unbeatable performance and reliability. With full traceability from raw materials through to finished goods, we supply the most advanced perfluoroelastomer products available. TRPlast® Perfluoroelastomer can be supplied as International Standard sized FFKM O-rings and custom moulded components. Buy FFKM products you can rely on from TRP Polymer Solutions today.

For more information about our custom moulded rubber seals, bespoke rubber mouldings or high-performance FFKM O-Rings, talk to one of our technical experts today.

Contact TRP Polymer Solutions on +44(0)1432 268899 or email us at sales@trp.co.uk.

Discuss your requirements with our engineers

Sometimes it's easier to just talk, contact us directly