Latest News

What is a permeation? – A study on fuel permeation of various seal materials

Permeation is the process in which molecules pass through a material. In many industries, this is sought to be minimised to prevent loss from within a system. In this guide from TRP, we discuss what permeation is, the various permeation processes, the results of our own permeation tests and which elastomers are best for your […]

Can You Laser Cut Rubber?

Can you laser cut rubber? Yes, here at TRP, we do so when we are producing products for our customers for low-volume production runs and for very short lead times, especially for initial prototypes. This blog explains how we use laser cutting in our processes and how we can utilise it to design and create […]

What is food-grade rubber? A guide to recent changes

Recent changes in FDA standards now mean that certain food-grade rubbers are no longer available. In this article, we discuss these recent changes in further depth. We also highlight our range of food-safe polymers and food-grade rubber products designed for food processing and contact applications. But, what is food-grade rubber and how do our products […]

What is FKM rubber?

FKM is a type of synthetic rubber known for its exceptional resistance to heat, chemicals, and oils. It was developed to address the need for a high-performance polymer with high resistance levels. At TRP Polymer, we manufacture FKM rubber for a number of different applications and industries. Continue reading to find out more. What is […]

What is perfluoroelastomer?

After the development of fluoroelastomers (FKM) in the 1950s, there was a high demand for a more chemically resistant polymer that had the ability to withstand much higher temperatures. By the late 1960s, this demand was met with the birth of perfluoroelastomers. But, what is perfluoroelastomer? Find out all the information in this guide from […]

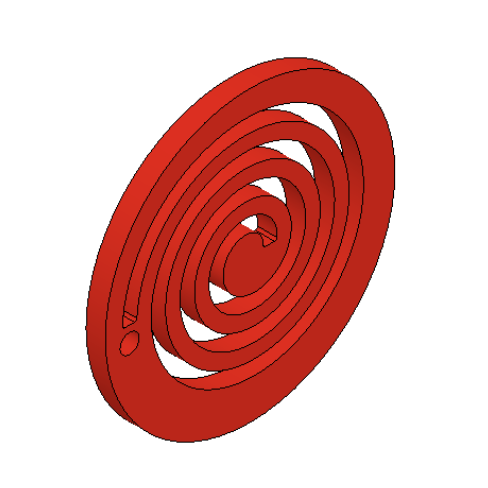

Mechanical Seals: How They Work

Mechanical seals are integral to the functionality and efficiency of various industrial systems. These contain fluid inside the components of a vessel or system, usually in a pump or mixing device. Though small, these seals play a big part in manufacturing processes across numerous industries and if one fails it can bring production to a […]

Sealing Solutions for Wind Turbines

Wind turbines are an incredibly popular source of renewable energy. This is not only because wind is an abundant source of energy, but it also provides electricity without burning fuel, which pollutes the air. Wind turbines require seals to help with efficiency and production. To find out about sealing solutions for wind turbines, continue reading […]

Renewable Biofuels & E-fuels

Using renewable biofuels and e-fuels is anticipated to be a key aspect of the world moving towards a more environmentally-friendly society by replacing fossil fuels that significantly harm the environment. At TRP Polymer, we’re moving with the times too and creating durable materials that are suitable for use with biofuels and synthetic fuels, such as […]

Gaskets for use in hydrogen electrolysis

When producing carbon-free hydrogen from renewable sources, electrolysis is an excellent choice. The process of electrolysis takes place in something called an electrolyser, which can range in size from small appliance-size equipment to larger scale production. So, what is hydrogen electrolysis? Continue reading our guide to discover more about hydrogen production of electrolysis. What are […]

Development of rubber materials used in the space sector

Rubber materials are popular in a wide range of industries, and none more so than in aviation and aerospace. Their durability and reliability make rubber materials an excellent choice for use in space. Certain rubber materials can withstand a range of aerospace fluids, rocket fuels, hydraulic fluids, oxidisers, and more. To find out more about […]